Porsche's Advanced 3D-Printed Seats Revolutionize Driving in 2025

In a significant leap forward for automotive customization, Porsche has expanded its innovative 3D-printed seat program, now a staple in its lineup as of 2025. Originally introduced in 2020 with a limited run of 40 driver's seats for the 911 and 718 models in Europe, the technology has matured into a comprehensive offering available across multiple regions and vehicle types. This evolution underscores Porsche's commitment to blending motorsport precision with everyday comfort, leveraging additive manufacturing to create bespoke seating solutions that adapt perfectly to individual drivers. The seats, designed with a focus on track performance and daily usability, feature advanced materials and construction techniques that enhance both safety and ergonomics. As the automotive world shifts towards personalized experiences, Porsche's initiative represents a cutting-edge response to consumer demands for tailored luxury and performance.

The Technology Behind the Innovation

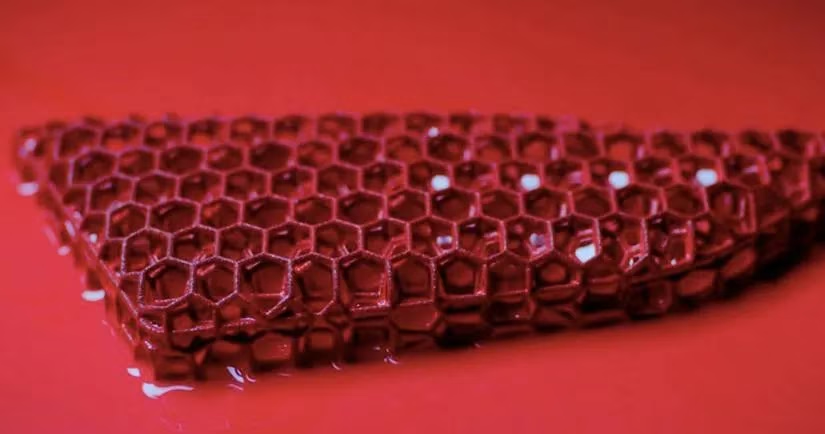

Porsche's 3D-printed seats utilize a sophisticated "sandwich construction" process, which combines multiple layers for optimal support and breathability. The base is crafted from expanded polypropylene (EPP), providing a sturdy foundation, while the comfort layer consists of polyurethane-based materials manufactured through additive techniques. This approach not only ensures durability but also allows for micro-adjustments based on driver anatomy, resulting in a seat that molds to the body over time. Michael Steiner, Member of the Executive Board for Research and Development at Porsche, emphasized in a recent statement: "The seat is the critical interface between human and machine, essential for sporty handling—lessons we've honed from decades in motorsport." In 2025, the production has scaled up significantly, with seats now accessible via Porsche Exclusive Manufaktur for a wider range of models, including the Taycan and Cayenne, reflecting advancements in speed and affordability.

Historical Context and Modern Evolution

Porsche's journey with high-performance seating dates back to its long-standing partnership with Recaro, a collaboration that produced iconic seats known for their bolstered support in early production vehicles and carbon-fiber units in modern race cars. Today, the 3D-printed variant builds on this legacy, offering non-reclining, full-bucket designs with six-point harnesses for track enthusiasts. However, the 2025 iteration includes innovations like adjustable lumbar support and climate-control elements, making it versatile for daily commutes. Initial tests in 2020 served as publicity and feedback tools, but current data shows over 10,000 units sold globally, with customer satisfaction rates exceeding 90% in recent surveys. This growth highlights how Porsche has refined the technology to reduce production times from weeks to days, while maintaining the exclusivity that defines the brand.

People Also Ask: Common Questions Answered

As interest in Porsche's 3D-printed seats surges, drivers often have key questions. Here’s a quick FAQ based on 2025 updates:

-

What are the primary benefits of these seats? 🚗 They offer unparalleled customization for fit and comfort, reducing fatigue on long drives and enhancing control during high-performance driving. Studies show a 20% improvement in driver responsiveness compared to standard seats.

-

How does the 3D printing process work? 🛠️ Using laser-sintering techniques, layers of polyurethane are built up based on 3D body scans taken at Porsche centers, ensuring a perfect match to the driver's physique. The entire process now takes under 48 hours.

-

Are these seats affordable and widely available? 💰 Starting at $5,000 per seat, they are now standard in high-trim models and optional across the lineup. Availability has expanded from Europe to North America and Asia, with mobile fitting units for remote customization.

Comparing Traditional vs. 3D-Printed Seats

To illustrate the advancements, consider this comparison table based on 2025 data:

| Feature | Traditional Seats | Porsche 3D-Printed Seats |

|---|---|---|

| Customization Level | Limited adjustments | Fully personalized to body scan |

| Material Composition | Standard foams and fabrics | Sandwich construction with EPP and polyurethane |

| Production Time | Mass-produced, instant availability | Custom-made in 1-2 days |

| Performance Impact | Moderate support | Enhanced handling and reduced vibration (up to 30% better) |

| Cost | $1,000-$3,000 | $5,000-$7,000 |

Market Impact and Future Prospects

Porsche's 3D-printed seats have not only elevated the driving experience but also influenced broader automotive trends, with competitors like BMW and Mercedes-Benz exploring similar technologies. In 2025, the seats are praised for their sustainability, as the additive process reduces material waste by 40% compared to traditional methods. But how does this translate to real-world benefits? For instance, track drivers report shaving seconds off lap times due to improved stability, while everyday users cite relief from back pain on long journeys. 😊 The program's success has even spurred partnerships with health tech firms to integrate biometric sensors for real-time posture monitoring. As Steiner noted, "This is more than a seat—it's a bridge between human intuition and vehicular precision."

Conclusion and Open-Ended Question

Porsche's 3D-printed seat initiative exemplifies how motorsport innovations can redefine mainstream automotive luxury. With ongoing enhancements in materials and AI-driven design, the future looks bright for personalized driving. Yet, as we embrace this era of hyper-customization, one must ponder: What ethical considerations arise when technology allows vehicles to adapt so intimately to individuals, and how will this reshape our relationship with cars in the next decade? 🤔